What Role Does Refrigeration Play in Ice Rinks?

At its most basic, refrigeration is based on the fact that heat always travels from a warm medium to a cooler one in an attempt to reach thermal equilibrium. This principle of thermodynamics forms the basis of how mechanically frozen ice rinks are created and maintained.

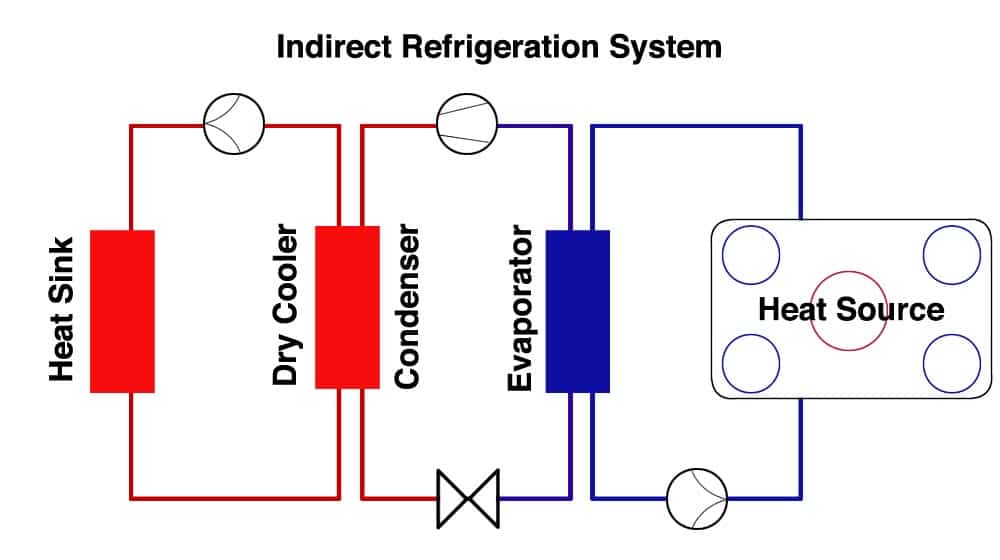

Until somewhat recently, indirect systems were the choice of refrigeration specialists and rink operators seeking safer control from the potentially harmful refrigerants used in such applications, such as ammonia, which is toxic, and to a much lesser degree, R-22 (in older systems), whose phase-out is well underway.

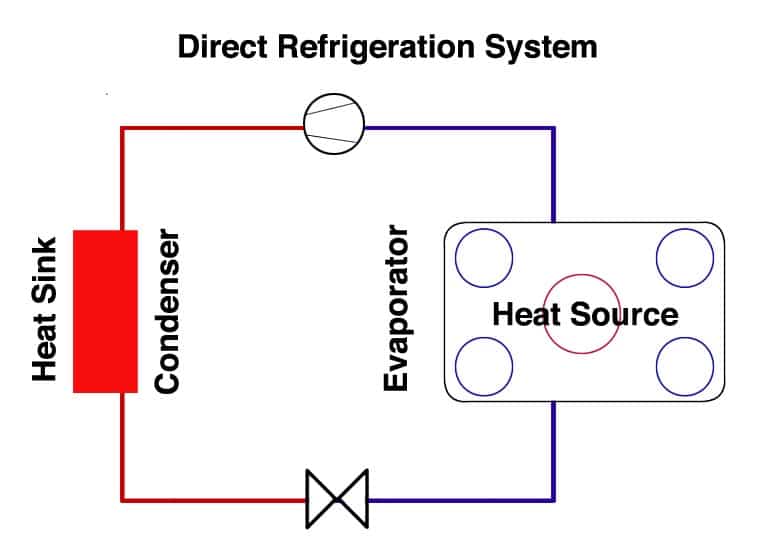

Over the past decade, CO2 has been gaining traction in ice rink applications. It was not until 2010 that the world’s first 100% CO2-based refrigeration system deployed in an ice rink was completed in Marcel Dutil Arena in Quebec, Canada. In 2012, a comparative study of refrigeration systems for ice rinks in Quebec was undertaken by Canada’s CanmetENERGY Research Centre. They compared 12 typical refrigeration systems currently offered for ice arenas in the market and found the CO2/R744 system as being the most energy efficient.

Hillphoenix has been at the forefront of CO2 refrigeration system technology and design over the past decade. The Hillphoenix CO2 booster system serves as an ideal solution for direct ice rink applications, capitalizing on the inherent advantages of CO2 as a refrigerant, including its thermal efficiency and environmentally benign, non-toxic and non-flammable nature.