Ice Rinks

Ice Rinks

An ice-skating rink is a frozen body of water or hardened chemicals where people can participate in a variety of winter sports including ice skating, ice hockey, speed skating, figure skating exhibitions, curling, ice shows, contests and more.

There are two types of ice rinks predominantly used today: “natural” ice rinks, where freezing occurs from cold ambient temperatures, and “mechanically frozen” ice rinks, where a coolant produces cold temperatures in the surface below the water, causing the surface water to freeze. The obvious advantage of mechanically frozen ice rinks is their ability to operate year-round regardless of outdoor ambient conditions.

Hillphoenix understands the criticality of the refrigeration process in creating and maintaining a quality sheet of ice for mechanically frozen rinks. Hillphoenix offers synthetic and innovative sustainable refrigeration solution such as CO2 systems.

What Role Does Hillphoenix Refrigeration Play in Ice Rinks?

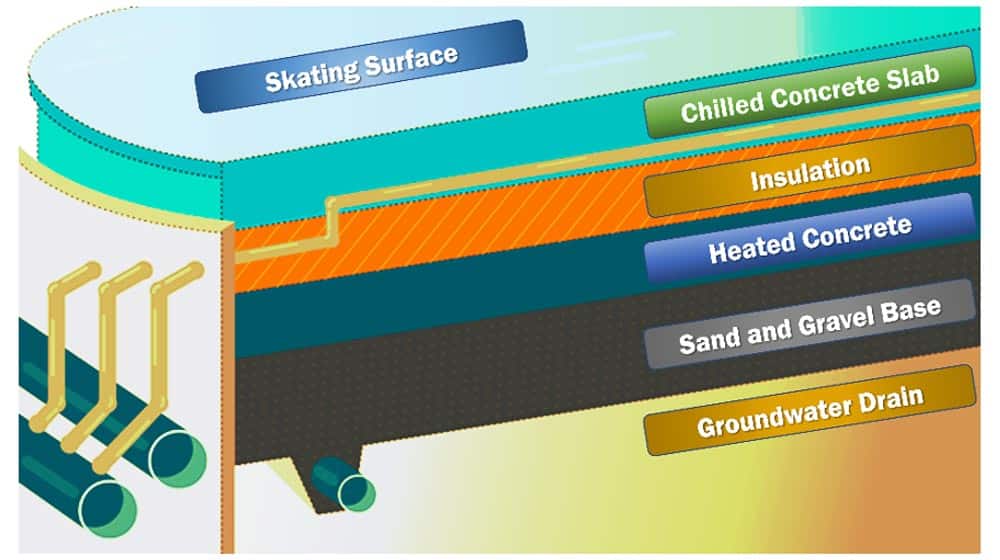

Ice Rink refrigeration systems can be one of two different types – direct or indirect. In an “indirect” refrigeration system, a liquid refrigerant absorbs heat from a secondary liquid, or brine, which then pulls heat out of a rink floor as the brine is pumped and circulated through pipes embedded evenly throughout the floor. In a “direct” system, the floor’s heat is removed by pumping the primary refrigerant directly through the floor’s pipes—there is no secondary coolant involved. Regardless of whether it is a direct or indirect system, the chilled liquid flowing through the pipes is kept at 32° F / 0° C, so that any water placed on top of the slab freezes and becomes the ice-skating surface that we see and use. A level of insulation is set beneath the concrete slab so that the ice can shrink and expand as needed.

Ice Rink refrigeration systems can be one of two different types – direct or indirect. In an “indirect” refrigeration system, a liquid refrigerant absorbs heat from a secondary liquid, or brine, which then pulls heat out of a rink floor as the brine is pumped and circulated through pipes embedded evenly throughout the floor. In a “direct” system, the floor’s heat is removed by pumping the primary refrigerant directly through the floor’s pipes—there is no secondary coolant involved. Regardless of whether it is a direct or indirect system, the chilled liquid flowing through the pipes is kept at 32° F / 0° C, so that any water placed on top of the slab freezes and becomes the ice-skating surface that we see and use. A level of insulation is set beneath the concrete slab so that the ice can shrink and expand as needed.

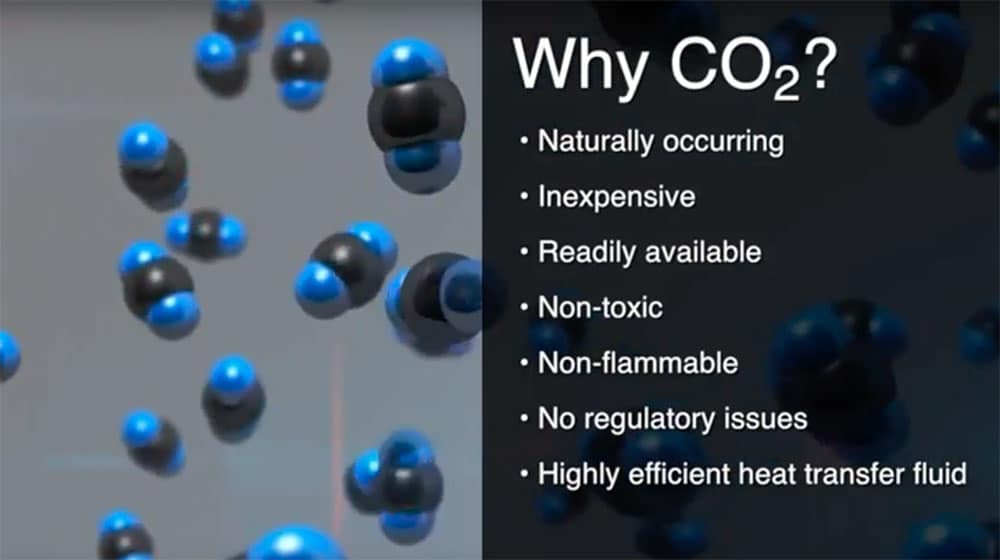

Over the past decade, CO2 has been gaining traction in ice rink applications. It was not until 2010 that the world’s first 100% CO2-based refrigeration system deployed in an ice rink was completed in Marcel Dutil Arena in Quebec, Canada. Hillphoenix has been at the forefront of CO2 refrigeration system technology and design over the past decade. The Hillphoenix CO2 booster system serves as an ideal solution for direct ice rink applications, capitalizing on the inherent advantages of CO2 as a refrigerant, including its thermal efficiency and environmentally benign, non-toxic and non-flammable nature.

Read more about the differences between direct and indirect rink systems >

Which Refrigerants Are Typically Used in Ice Rink Applications?

The Hillphoenix Transcritical CO2 Booster System for direct ice rink architectures delivers improved ice quality and pump power energy savings of up to 90% compared to traditional systems.

As of 2020, a major U.S. ice rink contractor reports installation of over 50 CO2 ice rinks across North America, which represents approximately 50% of their new rink installations. Based on the results the contractor has obtained, CO2 has become their first suggestion to customers for any future installation or retrofit.

Read more about the adoption of CO2 in the Ice Rink industry >

What Is the Outlook for the Recreational Ice Rink Market?

The Ice Rinks industry is expected to continue to benefit from the effects of pent-up demand (caused by COVID-19) in 2022, albeit at a lesser rate than 2021.

Industry profitability is expected to recover from lows related to the COVID-19 (coronavirus) pandemic. However, heightened overhead costs are expected to constrain growth in the average industry profit margin.

The Ice Rinks industry is projected to expand over the next five years, albeit total industry revenue will remain below prepandemic totals as a result of mandated ice rink closures as a result of COVID-19

What Role Does Hillphoenix Refrigeration Play in Ice Rinks?

Ice Rink refrigeration systems can be one of two different types – direct or indirect. In an “indirect” refrigeration system, a liquid refrigerant absorbs heat from a secondary liquid, or brine, which then pulls heat out of a rink floor as the brine is pumped and circulated through pipes embedded evenly throughout the floor. In a “direct” system, the floor’s heat is removed by pumping the primary refrigerant directly through the floor’s pipes—there is no secondary coolant involved. Regardless of whether it is a direct or indirect system, the chilled liquid flowing through the pipes is kept at 32° F / 0° C, so that any water placed on top of the slab freezes and becomes the ice-skating surface that we see and use. A level of insulation is set beneath the concrete slab so that the ice can shrink and expand as needed.

Over the past decade, CO2 has been gaining traction in ice rink applications. It was not until 2010 that the world’s first 100% CO2-based refrigeration system deployed in an ice rink was completed in Marcel Dutil Arena in Quebec, Canada. Hillphoenix has been at the forefront of CO2 refrigeration system technology and design over the past decade. The Hillphoenix CO2 booster system serves as an ideal solution for direct ice rink applications, capitalizing on the inherent advantages of CO2 as a refrigerant, including its thermal efficiency and environmentally benign, non-toxic and non-flammable nature.

Read more about the differences between direct and indirect rink systems >

Which Refrigerants Are Typically Used in Ice Rink Applications?

Traditionally, most ice rink operators using chillers as their refrigeration system have used ammonia as a primary refrigerant coupled with a brine or glycol as a secondary refrigerant. Within the past decade, carbon dioxide (CO2), a very common and inexpensive refrigerant which is free of the drawbacks of ammonia (e.g., toxicity, flammability, incompatibility with copper, etc.), has rapidly gained traction as a viable refrigerant for ice rink applications.

The Hillphoenix Transcritical CO2 Booster System for direct ice rink architectures delivers improved ice quality and pump power energy savings of up to 90% compared to traditional systems.

As of 2020, a major U.S. ice rink contractor reports installation of over 50 CO2 ice rinks across North America, which represents approximately 50% of their new rink installations. Based on the results the contractor has obtained, CO2 has become their first suggestion to customers for any future installation or retrofit.

Read more about the adoption of CO2 in the Ice Rink industry >

Recreational Ice Rink Insights

HVAC Testing Facility Achieves Optimal Temperatures With Hillphoenix Industrial CO2

An HVAC manufacturer approached the Hillphoenix Industrial engineering team with [...]

What Is the Outlook for the Ice Rink Market ?

The industry as a whole has an aging infrastructure and [...]

Which Refrigerants Are Typically Used in Ice Rink Applications?

Traditionally, most ice rink operators using chillers as their refrigeration [...]

What Role Does Refrigeration Play in Ice Rinks?

At its most basic, refrigeration is based on the fact [...]

Refrigeration Solutions for the Recreational Ice Rink Industry

CO2 Booster Systems

The Hillphoenix transcritical booster system, employing parallel rack architecture, utilizes only one refrigerant—the abundantly available, completely sustainable and economical CO2. CO2 is neither flammable nor toxic, making it ideal in terms of installation and system operation. Advansor is the most reliable and energy-efficient CO2 refrigeration system on the market.

Parallel Racks

Parallel Racks by Hillphoenix® are custom-designed platforms that offer the ultimate in flexibility, performance, and efficiency to the industrial refrigeration market. They are built around multiple compressors — however many the installation requires — linked in parallel to provide a host of benefits that are unique to this very robust architecture.

Synthetic HFC/HFO Systems

Until the recent emergence of CO2 as a viable industrial refrigerant alternative, industrial refrigeration systems have traditionally relied upon two refrigeration coolant technologies for decades: Ammonia for very large systems while synthetic halocarbon refrigerants account for the rest.

PowerCenter

PowerCenters are a completely modularized electrical distribution system in a custom enclosure. Multiple designs allow indoor and outdoor installation. Integrated electrical enclosures replace a conventionally built room while reducing footprint and clearance restrictions.

PowerWall

PowerWall is a cost-effective, flexible power distribution and control system for a wide variety of industrial applications. Totally integrated units arrive at the job site completely wired and pre-tested, reducing a significant part of the field contractor’s time.

Mechanical Centers

Mechanical Centers, designed for either indoor or outdoor placement, give you immediate flexibility as to where you wish to locate your refrigeration system equipment – on a slab behind your facility, a mezzanine inside, or on the roof.