Cold Storage

Cold Storage

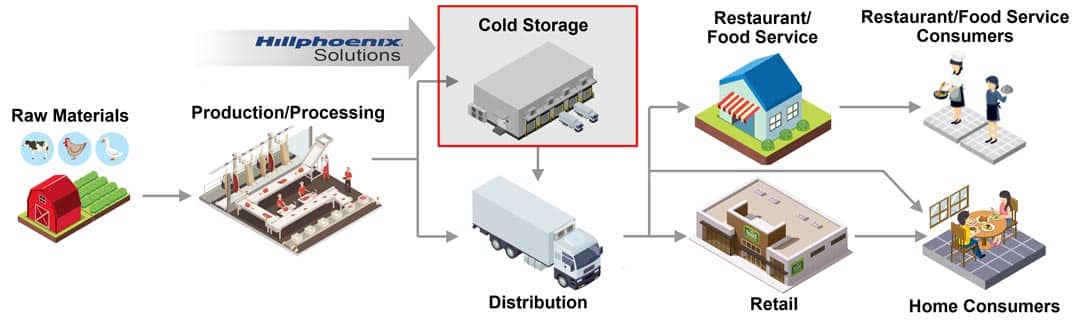

“Cold Storage” typically refers to that part of the global cold chain (see Food & Beverage image below) that provides refrigerated warehouse storage with multiple temperature and humidity zones for products and materials where maintaining the right environment is critical to keeping the quality of products intact and holding energy costs at a minimum. Cold storage is an essential part of the Food & Beverage and Pharmaceutical industries where it serves to prevent the growth of bacteria, reduce food waste, and to keep temperature-sensitive items at a constant cold temperature. The mission of industrial Cold Storage is preservation. The global Cold Storage market size was valued at USD 119.98 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 13.4% from 2022 to 2030.

Tapping on the expertise and collaborating with refrigeration solutions providers, like Hillphoenix, helps in the planning, designing, and correct placement of industrial Cold Storage systems to enable them to function effectively and efficiently for the long term. Hillphoenix helps companies ensure the integrity of the cold supply chain with innovative, traditional and sustainable Cold Storage refrigeration solutions. Hillphoenix has designed and installed custom, centralized industrial refrigeration equipment cooling millions of cubic feet of warehouse and distribution space throughout North America.

What Role Does Hillphoenix Refrigeration Play in Industrial Cold Storage?

Cold Storage is a fast growing but still relatively small subsector of the broader U.S. Industrial Refrigeration market. Much of the existing Cold Storage capacity is aging, with approximately half of such facilities having been built prior to 1990. While non-refrigerated warehouse/bulk distribution (“dry”) properties typically require little physical specialization, Industrial Cold Storage properties normally feature specialized, climate-controlled, refrigerated areas that fall into one of two general categories:

- COOLER OR COLD (33-39°F): Often referred to as a “refrigerated warehouse”, it is used to store perishables (e.g. fruits, vegetables, flowers, dairy, and meats) and maintain them at an optimum temperature to prevent any spoiling or otherwise degrading, and therefore, extend their life.

- FREEZER (0-32°F): Often referred to as a “freezer warehouse”, it must keep the product at a constant temperature at or below freezing to ensure there is no risk of damage or alteration to its integrity.

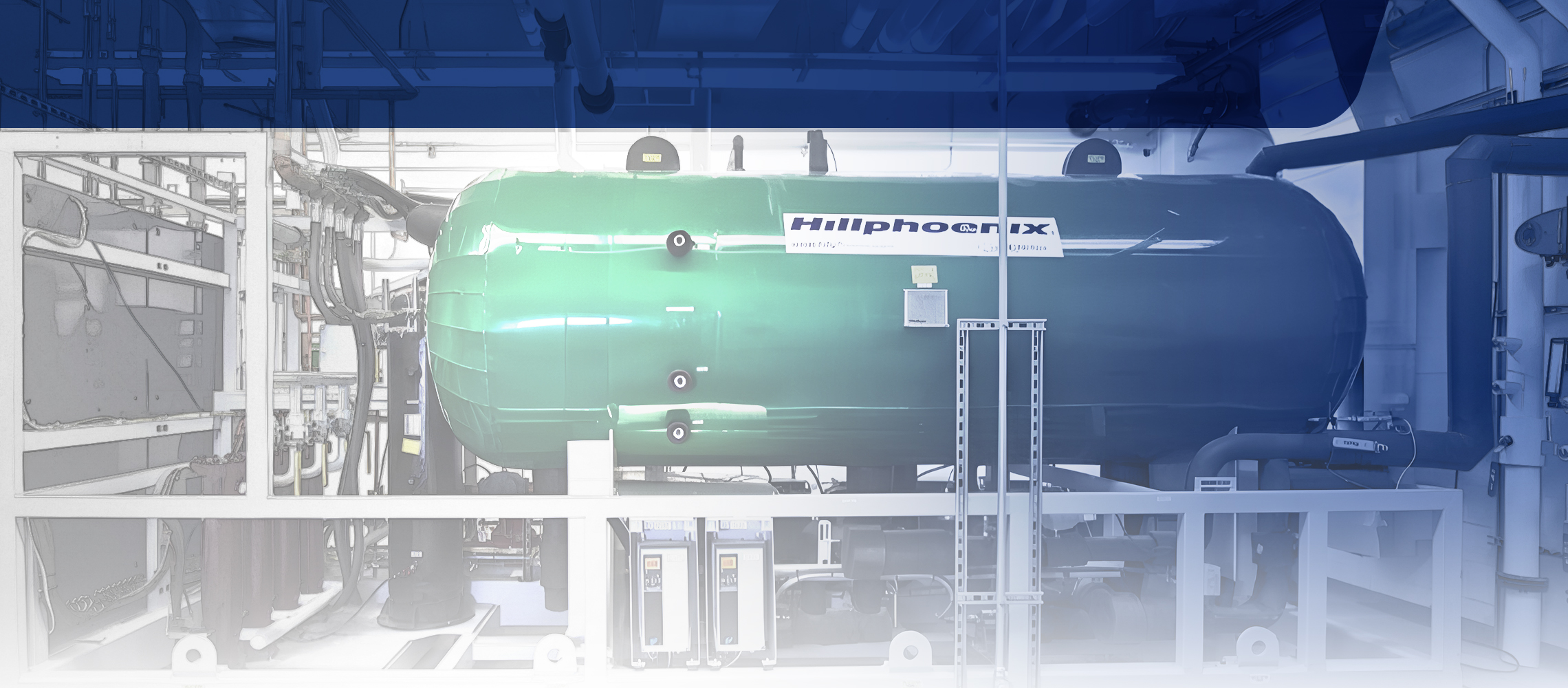

For any of these Cold Storage applications, Hillphoenix offers both traditional, synthetic refrigerant parallel rack systems or the Hillphoenix CO2 booster system. Industrial CO2 systems are gaining traction rapidly due to the multitude of benefits that natural refrigerants offer. Hillphoenix’s focus on driving CO2 technological innovation has made them the leader in the industry with solutions that make it possible and practical for businesses of all sizes and shapes to build cold storage infrastructures, food processing environments and warehousing and distribution facilities.

Read more about Hillphoenix Cold Storage refrigeration equipment >

Which Refrigerants Are Typically Used in an Industrial Cold Storage & Distribution Applications?

Hillphoenix understands that refrigerant selection is an important issue in terms of environment, safety and sustainability. Ammonia, CO2 and HFC/HFO refrigerants are the most common types used for industrial Cold Storage refrigeration systems. Through an intricate system of specially designed pipes, these gasses are compressed, transported, modified, and distributed to create the cooled air that the storage facility needs.

Although many cold stores currently operate using ammonia as a refrigerant, which has negligible GWP but is mildly flammable and toxic, the industry is increasingly looking at “lifetime” system costs and improved safety which often favor systems that may have higher initial costs but have lower energy costs, lower total cost of ownership (TCO) and are safer to operate, such as CO2 (R744).

A renewed look at these alternative natural refrigerants is being driven by the imminent phasing out of synthetic refrigerants due to their adverse environmental impact. The progress made in the technology and design of CO2 loops has increased the use of full CO2 refrigeration systems (such as the Hillphoenix CO2 booster system) utilizing R744 refrigerant. It is increasingly common to find these systems employed in both freezing and low-temperature warehouses.

In addition, Hillphoenix offers custom mechanical centers that protect people and refrigeration systems from outdoor environmental conditions. Since power and electrical systems are critical to refrigeration systems performance, we offer integrated PowerCenter and PowerWall systems that replace conventionally built rooms for indoor or outdoor applications. These custom enclosed electrical distribution systems and flexible power systems include gear, feeder and key control components and are offered in multiple configurations.

What Role Does Hillphoenix Refrigeration Play in Industrial Cold Storage?

Cold Storage is a fast growing but still relatively small subsector of the broader U.S. Industrial Refrigeration market. Much of the existing Cold Storage capacity is aging, with approximately half of such facilities having been built prior to 1990. While non-refrigerated warehouse/bulk distribution (“dry”) properties typically require little physical specialization, Cold Storage properties normally feature specialized, climate-controlled, refrigerated areas that fall into one of two general categories:

- COOLER OR COLD (33-39°F): Often referred to as a “refrigerated warehouse”, it is used to store perishables (e.g. fruits, vegetables, flowers, dairy, and meats) and maintain them at an optimum temperature to prevent any spoiling or otherwise degrading, and therefore, extend their life.

- FREEZER (0-32°F): Often referred to as a “freezer warehouse”, it must keep the product at a constant temperature at or below freezing to ensure there is no risk of damage or alteration to its integrity.

For any of these Cold Storage applications, Hillphoenix offers both traditional, synthetic refrigerant parallel rack systems or the Hillphoenix CO2 booster system. CO2 systems are gaining traction rapidly due to the multitude of benefits that natural refrigerants offer. Hillphoenix’s focus on driving CO2 technological innovation has made them the leader in the industry with solutions that make it possible and practical for businesses of all sizes and shapes to build cold storage infrastructures, food processing environments and warehousing and distribution facilities.

Read more about Hillphoenix Cold Storage refrigeration equipment >

Which Refrigerants Are Typically Used in an Industrial Cold Storage & Distribution Applications?

Hillphoenix understands that refrigerant selection is an important issue in terms of environment, safety and sustainability. Ammonia, CO2 and HFC/HFO refrigerants are the most common types used for industrial Cold Storage refrigeration systems. Through an intricate system of specially designed pipes, these gasses are compressed, transported, modified, and distributed to create the cooled air that the storage facility needs.

Although many cold stores currently operate using ammonia as a refrigerant, which has negligible GWP but is mildly flammable and toxic, the industry is increasingly looking at “lifetime” system costs and improved safety which often favor systems that may have higher initial costs but have lower energy costs, lower total cost of ownership (TCO) and are safer to operate, such as CO2 (R744).

A renewed look at these alternative natural refrigerants is being driven by the imminent phasing out of synthetic refrigerants due to their adverse environmental impact. The progress made in the technology and design of CO2 loops has increased the use of full CO2 refrigeration systems (such as the Hillphoenix CO2 booster system) utilizing R744 refrigerant. It is increasingly common to find these systems employed in both freezing and low-temperature warehouses.

In addition, Hillphoenix offers custom mechanical centers that protect people and refrigeration systems from outdoor environmental conditions. Since power and electrical systems are critical to refrigeration systems performance, we offer integrated PowerCenter and PowerWall systems that replace conventionally built rooms for indoor or outdoor applications. These custom enclosed electrical distribution systems and flexible power systems include gear, feeder and key control components and are offered in multiple configurations.

What Is the Outlook for the Industrial Cold Storage Market?

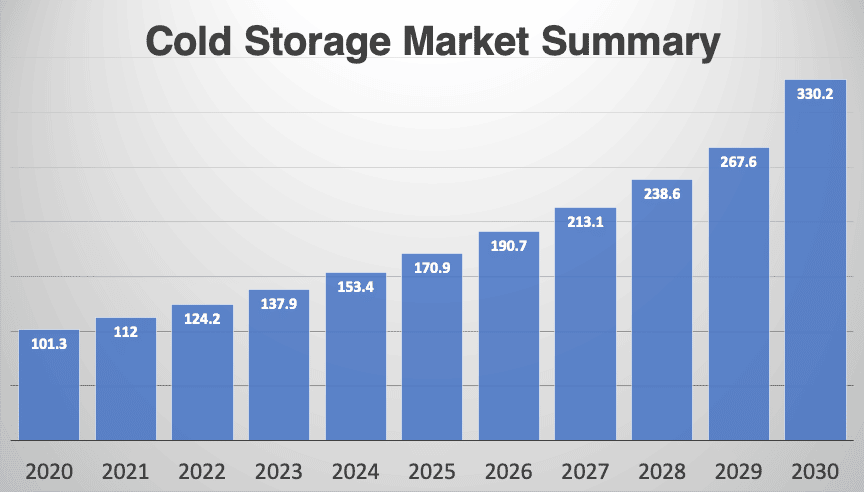

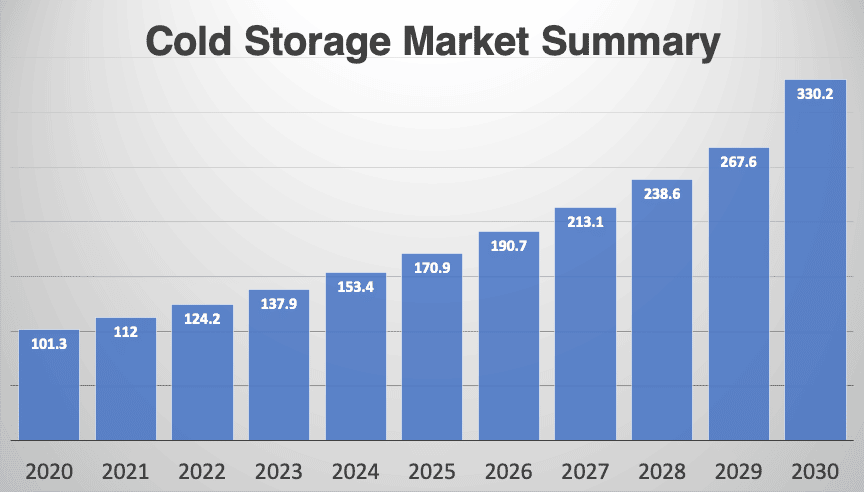

The global cold storage market size was valued at USD 119.98 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 13.4% from 2022 to 2030. The market has benefitted significantly from the stringent regulations governing the production and supply of temperature-sensitive products. The industry is poised for unprecedented growth over the forecast period on account of growing organized retail sectors in the emerging economies.

What Role Does Hillphoenix Refrigeration Play in Industrial Cold Storage?

Cold Storage is a fast growing but still relatively small subsector of the broader U.S. Industrial Refrigeration market. Much of the existing Cold Storage capacity is aging, with approximately half of such facilities having been built prior to 1990. While non-refrigerated warehouse/bulk distribution (“dry”) properties typically require little physical specialization, Cold Storage properties normally feature specialized, climate-controlled, refrigerated areas that fall into one of two general categories:

- COOLER OR COLD (33-39°F): Often referred to as a “refrigerated warehouse”, it is used to store perishables (e.g. fruits, vegetables, flowers, dairy, and meats) and maintain them at an optimum temperature to prevent any spoiling or otherwise degrading, and therefore, extend their life.

- FREEZER (0-32°F): Often referred to as a “freezer warehouse”, it must keep the product at a constant temperature at or below freezing to ensure there is no risk of damage or alteration to its integrity.

For any of these Cold Storage applications, Hillphoenix offers both traditional, synthetic refrigerant parallel rack systems or the Hillphoenix CO2 booster system. CO2 systems are gaining traction rapidly due to the multitude of benefits that natural refrigerants offer. Hillphoenix’s focus on driving CO2 technological innovation has made them the leader in the industry with solutions that make it possible and practical for businesses of all sizes and shapes to build cold storage infrastructures, food processing environments and warehousing and distribution facilities.

Read more about Hillphoenix Cold Storage refrigeration equipment >

Which Refrigerants Are Typically Used in an Industrial Cold Storage & Distribution Applications?

Hillphoenix understands that refrigerant selection is an important issue in terms of environment, safety and sustainability. Ammonia, CO2 and HFC/HFO refrigerants are the most common types used for industrial Cold Storage refrigeration systems. Through an intricate system of specially designed pipes, these gasses are compressed, transported, modified, and distributed to create the cooled air that the storage facility needs.

Although many cold stores currently operate using ammonia as a refrigerant, which has negligible GWP but is mildly flammable and toxic, the industry is increasingly looking at “lifetime” system costs and improved safety which often favor systems that may have higher initial costs but have lower energy costs, lower total cost of ownership (TCO) and are safer to operate, such as CO2 (R744).

A renewed look at these alternative natural refrigerants is being driven by the imminent phasing out of synthetic refrigerants due to their adverse environmental impact. The progress made in the technology and design of CO2 loops has increased the use of full CO2 refrigeration systems (such as the Hillphoenix CO2 booster system) utilizing R744 refrigerant. It is increasingly common to find these systems employed in both freezing and low-temperature warehouses.

Learn more about Hillphoenix CO2 and HFC system solutions >

In addition, Hillphoenix offers custom mechanical centers that protect people and refrigeration systems from outdoor environmental conditions. Since power and electrical systems are critical to refrigeration systems performance, we offering integrated PowerCenter and PowerWall systems that replace conventionally built rooms for indoor or outdoor applications. These custom enclosed electrical distribution systems and flexible power systems include gear, feeder and key control components and are offered in multiple configurations.

What Is the Outlook for the Industrial Cold Storage Market?

The global cold storage market size was valued at USD 119.98 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 13.4% from 2022 to 2030. The market has benefitted significantly from the stringent regulations governing the production and supply of temperature-sensitive products. The industry is poised for unprecedented growth over the forecast period on account of growing organized retail sectors in the emerging economies.

Cold Storage Insights

Which Refrigerants Are Typically Used in Industrial Cold Storage Applications?

Hillphoenix understands that refrigerant selection is an important issue in [...]

Industrial CO2 Refrigerant: Answers to Frequently Asked Questions You Need to Know

The use of CO2 as a refrigerant in the industrial [...]

How Does the Finalized AIM Act Rule Impact Your Operation?

Earlier this month, the EPA announced its final ruling on [...]

Which Refrigerants Are Typically Used in Industrial Cold Storage Applications?

Hillphoenix understands that refrigerant selection is an important issue in [...]

Refrigeration Solutions for the Cold Storage Warehouse Industry

CO2 Booster Systems

The Hillphoenix transcritical booster system, employing parallel rack architecture, utilizes only one refrigerant—the abundantly available, completely sustainable and economical CO2. CO2 is neither flammable nor toxic, making it ideal in terms of installation and system operation. Advansor is the most reliable and energy-efficient CO2 refrigeration system on the market.

Parallel Racks

Parallel Racks by Hillphoenix® are custom-designed platforms that offer the ultimate in flexibility, performance, and efficiency to the industrial refrigeration market. They are built around multiple compressors — however many the installation requires — linked in parallel to provide a host of benefits that are unique to this very robust architecture.

Synthetic HFC/HFO Systems

Until the recent emergence of CO2 as a viable industrial refrigerant alternative, industrial refrigeration systems have traditionally relied upon two refrigeration coolant technologies for decades: Ammonia for very large systems while synthetic halocarbon refrigerants account for the rest.

PowerCenter

PowerCenters are a completely modularized electrical distribution system in a custom enclosure. Multiple designs allow indoor and outdoor installation. Integrated electrical enclosures replace a conventionally built room while reducing footprint and clearance restrictions.

PowerWall

PowerWall is a cost-effective, flexible power distribution and control system for a wide variety of industrial applications. Totally integrated units arrive at the job site completely wired and pre-tested, reducing a significant part of the field contractor’s time.

Mechanical Centers

Mechanical Centers, designed for either indoor or outdoor placement, give you immediate flexibility as to where you wish to locate your refrigeration system equipment – on a slab behind your facility, a mezzanine inside, or on the roof.