Pharmaceutical

Pharmaceutical

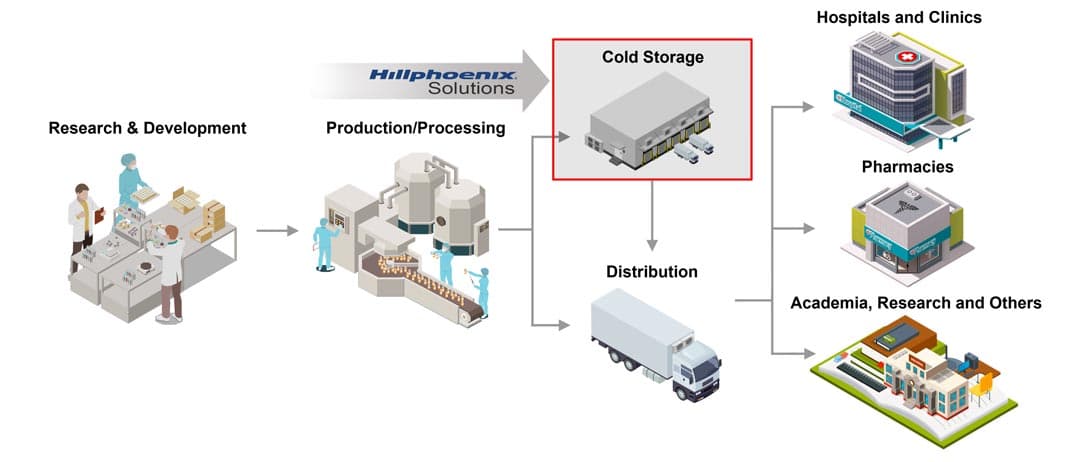

For companies involved in the manufacture of pharmaceutical products, the regulatory and safety issues are myriad. Hillphoenix understands the added emphasis on refrigeration systems providing very precise temperature control for proper process cooling and cold storage (see cold chain image below), given the high monetary value of the involved products and the strict nature of the regulatory requirements affecting them.

Our dedicated industrial refrigeration team at Hillphoenix designs, engineers, and manufactures innovative, synthetic and sustainable CO2 refrigeration solutions to meet critical process requirements for the Cold Storage needs of the pharmaceutical process.

What Role Does Hillphoenix Industrial Refrigeration Play in the Pharmaceutical Process?

The pharmaceutical industry is based around operations where adherence to strict conditions and maintenance of critical parameters are essential to the success of every step of the process. Refrigerated storage (cold storage) is certainly one aspect of this and is widely used in the pharmaceutical industry.

There are basically four different storage categories in pharmaceutical:

- Room temperature – Many of the pharmaceutical process activities are conducted at room temperature, which is defined as 20° C to 25°

- Cool storage conditions – Some drug substances that degrade at room temperature are stored at cool storage conditions, which are defined as 8° C to 15° C

- Cold storage conditions – Highly degradable drugs, vitamins, and chemicals are stored in cold conditions ranging from 2° C to 8° This temperature decreases the rate of chemical reactions as well as microbial growth.

- Fridge storage conditions – Storage in temperatures of -4° C to 2°C is considered as fridge storage.

The stored goods are often high-value products, such as finished goods, products that are used in the production process to make other goods, safety stock or buffer inventory, and/or cells of a specific genome for the purpose of future use in a product or medicinal needs. The common denominator, in most cases, is that the stored goods must be maintained within a precise temperature range since they are sensitive to temperature fluctuations. Loss of refrigeration may not only cause high monetary losses but may also cause undesired production and supply chain disturbances or increase the business risk exposure through the loss of a buffer (safety) stock.

Hillphoenix, the leader in CO2 refrigeration and alternative refrigerants, provides custom industrial refrigeration systems to meet the critical process requirements for cold storage of pharmaceuticals. The innovative traditional and sustainable refrigeration solutions of Hillphoenix have handled refrigeration applications of all sizes.

Whether it’s Hillphoenix synthetic refrigerant parallel rack systems or the Hillphoenix CO2 booster system, Hillphoenix cold box refrigeration solutions are the perfect fit for addressing the critical needs of refrigerated storage in the pharmaceutical industry segment.

Which Refrigerants Are Used in Pharmaceutical Refrigerated Storage?

Most cold storage facilities utilize either ammonia (NH3), carbon dioxide (CO2), or HFC/HFO compounds as their refrigerant. Although ammonia is currently the most commonly used refrigerant in facilities that have large-scale refrigeration systems, such as food and beverage manufacturing facilities and cold storage warehouses, CO2 has gained popularity as the refrigerant of choice in facilities with freezer applications since it works so well at low temperatures. One advantage of CO2 is that it doesn’t possess the same risks of toxicity and explosion as ammonia does when substantial gas leaks are undetected to the point where the concentration level and/or length of exposure exceeds safe limits. For this reason, ammonia leak detection systems are often installed to help reduce these risks and provide safety.

The renewed look at CO2 and ammonia as alternative, natural refrigerants is driven by the imminent phasing out of synthetic refrigerants due to their adverse environmental impacts. Several looming refrigeration regulations putting limits on refrigerant charge and incentivizing compliance are pushing business owners to switch to more environmentally safe alternatives, such as CO2 and ammonia.

When it comes to deciding whether to use synthetic, CO2 or ammonia in your business, it depends on the specific nature of the application, the type of facility and location involved, the available budget, and the facility’s existing physical condition.

Hillphoenix has capitalized on the multitude of benefits of CO2 as a refrigerant and offers some of the best natural refrigerant solutions available for use today. CO2 is being increasingly used, and the technological innovation occurring in the industry with equipment and natural refrigerants continues apace. The use of a CO2 system in industrial applications makes it possible and practical for businesses of all sizes to build cold storage infrastructures.

What Is the Outlook for the Pharmaceutical Market?

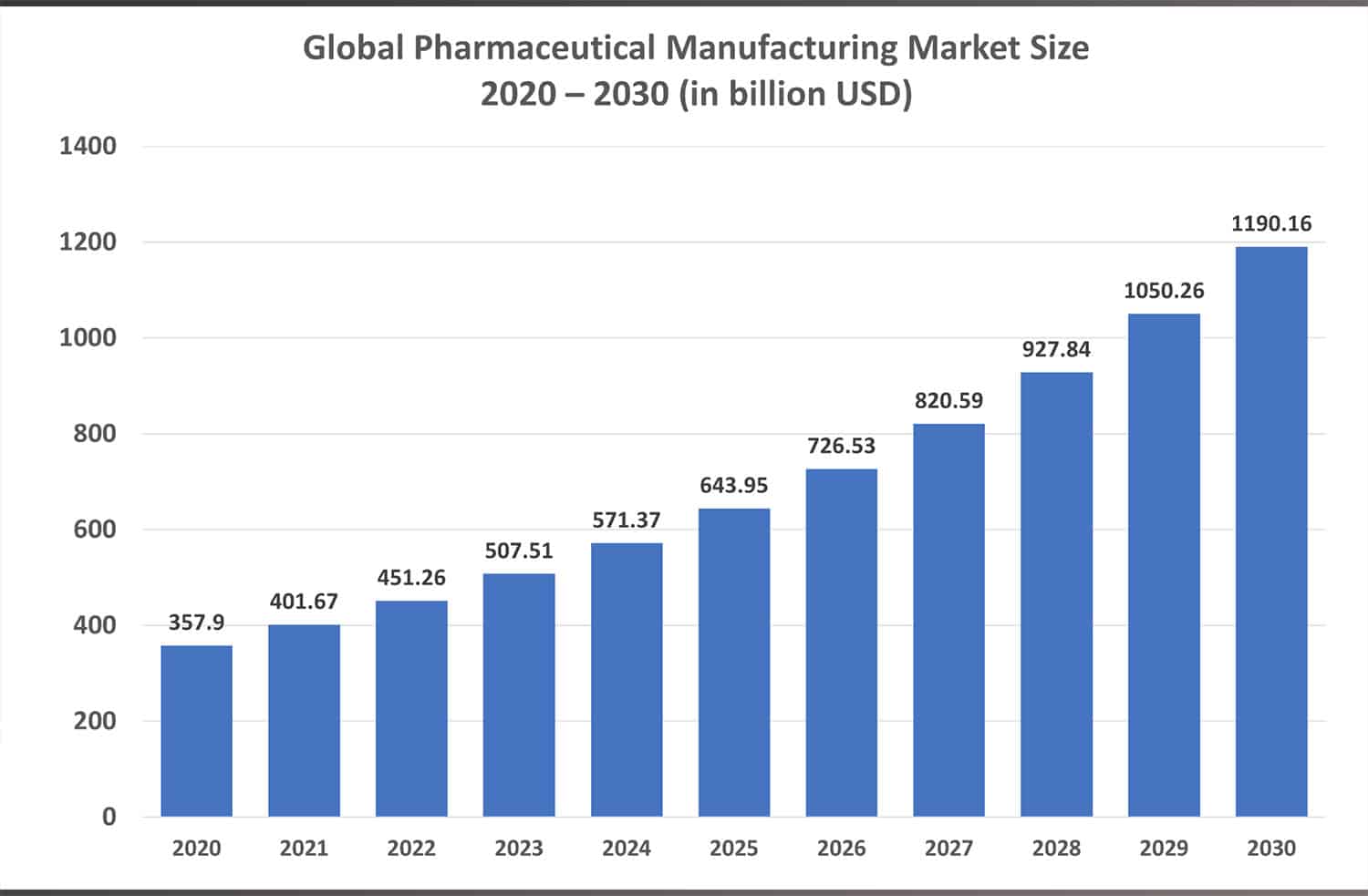

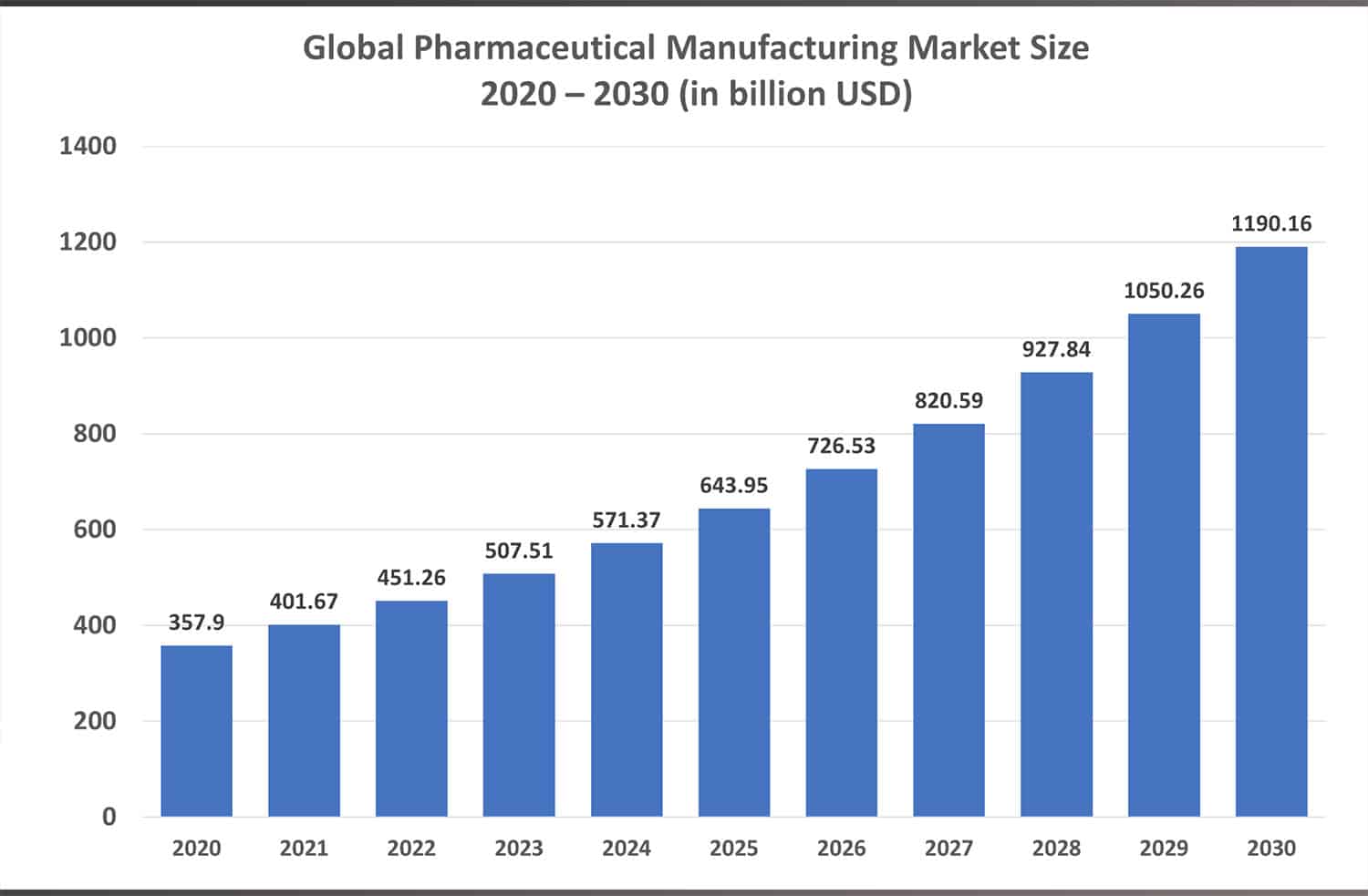

The global pharmaceutical manufacturing market revenue (which is a portion of the total global pharmaceutical revenue) came in at $357.9 billion USD in 2020 and is predicted to reach $1,190.2 billion USD by 2030, poised to grow at a robust 12.8% CAGR during the forecast period of 2021 to 2030.

What Role Does Hillphoenix Industrial Refrigeration Play in the Pharmaceutical Process?

The pharmaceutical industry is based around operations where adherence to strict conditions and maintenance of critical parameters are essential to the success of every step of the process. Refrigerated storage (cold storage) is certainly one aspect of this and is widely used in the pharmaceutical industry.

There are basically four different storage categories in pharmaceutical:

- Room temperature – Many of the pharmaceutical process activities are conducted at room temperature, which is defined as 20° C to 25°

- Cool storage conditions – Some drug substances that degrade at room temperature are stored at cool storage conditions, which are defined as 8° C to 15° C

- Cold storage conditions – Highly degradable drugs, vitamins, and chemicals are stored in cold conditions ranging from 2° C to 8° This temperature decreases the rate of chemical reactions as well as microbial growth.

- Fridge storage conditions – Storage in temperatures of -4° C to 2°C is considered as fridge storage.

The stored goods are often high-value products, such as finished goods, products that are used in the production process to make other goods, safety stock or buffer inventory, and/or cells of a specific genome for the purpose of future use in a product or medicinal needs. The common denominator, in most cases, is that the stored goods must be maintained within a precise temperature range since they are sensitive to temperature fluctuations. Loss of refrigeration may not only cause high monetary losses but may also cause undesired production and supply chain disturbances or increase the business risk exposure through the loss of a buffer (safety) stock.

Hillphoenix, the leader in CO2 refrigeration and alternative refrigerants, provides custom industrial refrigeration systems to meet the critical process requirements for cold storage of pharmaceuticals. The innovative traditional and sustainable refrigeration solutions of Hillphoenix have handled refrigeration applications of all sizes.

Whether it’s Hillphoenix synthetic refrigerant parallel rack systems or the Hillphoenix CO2 booster system, Hillphoenix cold box refrigeration solutions are the perfect fit for addressing the critical needs of refrigerated storage in the pharmaceutical industry segment.

Visit our product solutions >

Which Refrigerants Are Used in Pharmaceutical Refrigerated Storage?

Pharmaceutical companies that deal with medicines use cold storage warehouses very often to store syrups, injections, etc. and protect them from denaturation. These warehouses are temperature-controlled and climate-controlled spaces with state-of-the-art control and monitoring equipment to provide specific environmental conditions. Cold temperature prevents the pharmaceutical materials from getting ruined by contamination.

Most cold storage facilities utilize either ammonia (NH3), carbon dioxide (CO2), or HFC/HFO compounds as their refrigerant. Although ammonia is currently the most commonly used refrigerant in facilities that have large-scale refrigeration systems, such as food and beverage manufacturing facilities and cold storage warehouses, CO2 has gained popularity as the refrigerant of choice in facilities with freezer applications since it works so well at low temperatures. One advantage of CO2 is that it doesn’t possess the same risks of toxicity and explosion as ammonia does when substantial gas leaks are undetected to the point where the concentration level and/or length of exposure exceeds safe limits. For this reason, ammonia leak detection systems are often installed to help reduce these risks and provide safety.

The renewed look at CO2 and ammonia as alternative, natural refrigerants is driven by the imminent phasing out of synthetic refrigerants due to their adverse environmental impacts. Several looming refrigeration regulations putting limits on refrigerant charge and incentivizing compliance are pushing business owners to switch to more environmentally safe alternatives, such as CO2 and ammonia.

When it comes to deciding whether to use synthetic, CO2 or ammonia in your business, it depends on the specific nature of the application, the type of facility and location involved, the available budget, and the facility’s existing physical condition.

Hillphoenix has capitalized on the multitude of benefits of CO2 as a refrigerant and offers some of the best natural refrigerant solutions available for use today. CO2 is being increasingly used, and the technological innovation occurring in the industry with equipment and natural refrigerants continues apace. The use of a CO2 system in industrial applications makes it possible and practical for businesses of all sizes to build cold storage infrastructures.

What Is the Outlook for the Pharmaceutical Market?

The global pharmaceutical manufacturing market revenue (which is a portion of the total global pharmaceutical revenue) came in at $357.9 billion USD in 2020 and is predicted to reach $1,190.2 billion USD by 2030, poised to grow at a robust 12.8% CAGR during the forecast period of 2021 to 2030.

Pharmaceutical Insights

CO2 vs. NH3 Properties, Pros & Cons

Ammonia has long been widely used in a variety of [...]

What Is the Outlook for the Pharmaceutical Market?

The global pharmaceutical market (excluding vaccines) saw revenues of $1.48 [...]

Meat Processing Plant Expansion Made Simple With CO2 Expertise from Hillphoenix Industrial

When a boutique meat processor needed to double capacity, they [...]

Hillphoenix Industrial CO2 System Streamlines Operation for Industrial Produce Storage Facility

When a produce farm began exploring sustainable and efficient upgrades [...]

Refrigeration Solutions for the Pharmaceutical Industries

PowerCenter

PowerCenters are a completely modularized electrical distribution system in a custom enclosure. Multiple designs allow indoor and outdoor installation. Integrated electrical enclosures replace a conventionally built room while reducing footprint and clearance restrictions.

Parallel Racks

Parallel Racks by Hillphoenix® are custom-designed platforms that offer the ultimate in flexibility, performance, and efficiency to the industrial refrigeration market. They are built around multiple compressors — however many the installation requires — linked in parallel to provide a host of benefits that are unique to this very robust architecture.

Mechanical Centers

Mechanical Centers, designed for either indoor or outdoor placement, give you immediate flexibility as to where you wish to locate your refrigeration system equipment – on a slab behind your facility, a mezzanine inside, or on the roof.

PowerCenter

PowerCenters are a completely modularized electrical distribution system in a custom enclosure. Multiple designs allow indoor and outdoor installation. Integrated electrical enclosures replace a conventionally built room while reducing footprint and clearance restrictions.

PowerWall

PowerWall is a cost-effective, flexible power distribution and control system for a wide variety of industrial applications. Totally integrated units arrive at the job site completely wired and pre-tested, reducing a significant part of the field contractor’s time.

Mechanical Centers

Mechanical Centers, designed for either indoor or outdoor placement, give you immediate flexibility as to where you wish to locate your refrigeration system equipment – on a slab behind your facility, a mezzanine inside, or on the roof.