Cold Storage and Refrigeration

Cold Storage is a fast growing but still relatively small subsector of the broader U.S. Industrial Refrigeration market. Much of the existing Cold Storage capacity is aging, with approximately half of such facilities having been built prior to 1990. While non-refrigerated warehouse/bulk distribution (“dry”) properties typically require little physical specialization, Cold Storage properties normally feature specialized, climate-controlled, refrigerated areas that fall into one of two general categories:

- COOLER OR COLD (33-39°F):Often referred to as a “refrigerated warehouse”, it is used to store perishables (e.g. fruits, vegetables, flowers, dairy, and meats). A refrigerated warehouse aims to maintain the products at an optimum temperature to stop them from spoiling or otherwise degrading, and therefore, extend their usable life.

- FREEZER (0-32°F):Often referred to as a “freezer warehouse”, it must keep the product at a constant temperature at or below freezing to ensure there is no risk of damage or alteration to its integrity. Generally, these are used to store frozen vegetables, fruit, fish, meat, seafood, and biopharmaceuticals.

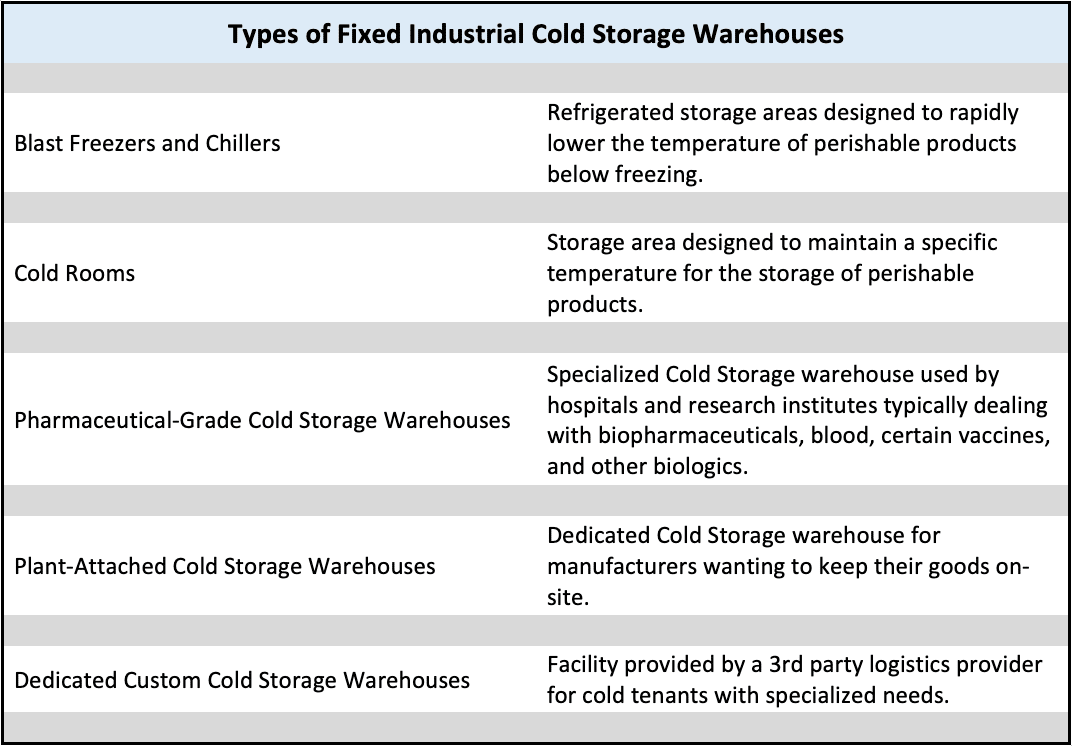

The decision of whether to use refrigerated warehousing or freezer warehousing is based on the specific products intended for storage. There are several different types of fixed (e.g., excludes refrigerated shipping containers) Cold Storage warehouses. The most common are: