Ammonia (R-717) Refrigerant

Ammonia has been in continuous use as an industrial refrigerant longer than any other. It is in fact among the first refrigerants to be commonly used in industrial applications and remains one of the most widely used today.

Ammonia has been in continuous use as an industrial refrigerant longer than any other. It is in fact among the first refrigerants to be commonly used and remains one of the most widely used today.

Ammonia is also one of the most efficient alternative refrigerants in use. That use, however, is almost entirely limited to industrial manufacturing and distribution applications due to ammonia’s single largest drawback; its high toxicity.

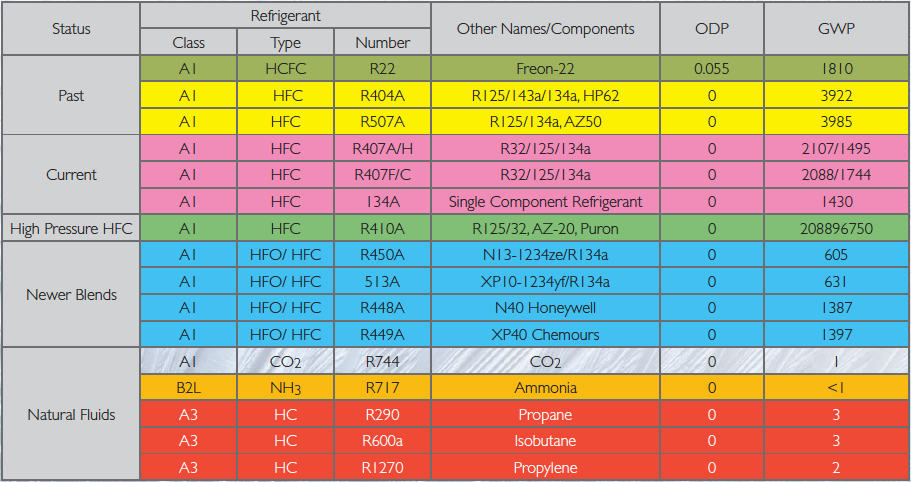

Ammonia (R-717) is unique among industrial refrigerants currently in use in that it is not a halocarbon like most other commonly used refrigerants. It is a naturally occurring chemical (NH3) that consists of nitrogen and hydrogen. Almost  all other refrigerants are a combination of carbon and halogens, the group of elements that includes fluorine and chlorine. This factor sets ammonia apart from the vast majority of other refrigerants by limiting its effects on the environment. It has an Ozone Depletion Potential (ODP) rating and a Global Warming Potential (GWP) rating of 0. Only CO2 comes close with a GWP of 1.

all other refrigerants are a combination of carbon and halogens, the group of elements that includes fluorine and chlorine. This factor sets ammonia apart from the vast majority of other refrigerants by limiting its effects on the environment. It has an Ozone Depletion Potential (ODP) rating and a Global Warming Potential (GWP) rating of 0. Only CO2 comes close with a GWP of 1.

Not only is its benign effect on the environment a point in favor of its use, but ammonia has excellent qualities as a refrigerant. It has for instance, the highest refrigerating capacity per pound of any refrigerant and a number of other outstanding thermal properties that make it popular for many industrial refrigeration applications.

With regards to R-404A, the main alternative to ammonia in industrial, processing and manufacturing applications, the two are nearly equal in various factors of their efficiency. R-404A is more commonly used in Europe for these types of applications whereas ammonia predominates domestically. According to one analysis, “in terms of relationship saturation temperature/pressure, volumetric cooling capacity, thermodynamic efficiency of the reference ideal cycle” they are practically equivalent. R-717 however, does have certain comparative advantages.

Ammonia Refrigeration for Cold Storage Applications

One of the most important factors in a refrigerant’s performance is its heat transfer capability. The boiling point of R-410A is -55°F but for ammonia it’s only -28°F, almost half of that of R-410A which indicates that much less energy is required to achieve the same amount of work, or in the case of refrigeration — cooling.

When comparing the efficiency of compression process using reciprocating compressors, ammonia only performs at a modest 10% edge over R-404A. But with screw compressors, ammonia’s advantage increases hand-in-hand with increases in the pressure ratio employed.

A further benefit of R-717 flows directly from its efficiency. An ammonia-based system requires less electricity, resulting in lower operating costs. When used with screw compressors, ammonia requires less energy to achieve the same efficiencies compared to R-404A.

Even compared to other refrigerants, ammonia also performs favorably. In fact, it does so well, a CO2 (R-744) compressor manufacturer recently touted a study that showed that with their compressors (enhanced) R-744 systems have finally reached parity with R-717 systems in warmer climates. The report goes on to say that in cooler climates these systems have even achieved gains over ammonia systems. But CO2 still entails some perceived challenges for some operators. These include higher operating pressures that require the use of specialized piping and the need for CO2-specific control valves and a type of condenser that also works as a gas cooler under certain conditions. Although CO2 is like NH3, a refrigerant that’s been around for a very long time, it is still fairly new to many perspective users.

Another consequence of ammonia’s high volumetric cooling capacity of is the need for less piping than would be required for halogenated refrigerants. Narrower diameter pipe can be used with R-717. This in turn further lowers the cost of using ammonia by making installations less expensive with less piping needed.

On the flip side of ammonia’s consideration, it tends to become corrosive to copper, brass and other non-ferrous materials when it combines with water. Copper is commonly used in refrigeration equipment for halocarbon systems. It’s not an option for systems using R-717. Another concern is its behavior with oil. As with almost any mechanical system, refrigeration systems require lubrication to reduce friction in moving parts extend their durability. Ammonia is non-miscible with oil, so systems in which it’s used must be designed to account for this characteristic and prevent oil from pooling in heat exchangers and thereby reducing efficiency.

Ammonia’s Limitations

On the basis of environmental and performance factors, ammonia would seem to be an excellent choice. But there are other considerations that come into play when assessing its practicality for various applications in industrial and distribution facilities’ use.

In a particularly a bad string of events in 2016 that included an ammonia leak at a Shamrock Farms facility in Phoenix which resulted that April in multiple people complaining of burning eyes. A month earlier, a Boston warehouse worker died from an ammonia leak. And a month before that, nine people were sickened from a leak at a Brazilian fertilizer plant. In December of 2015, two men working in a nitrogen plant in Canada were sent to the hospital after an ammonia leak. One succumbed to his injuries.

A meat processing plant in South Carolina experienced an ammonia leak in 2018 that fortunately did not result in any deaths or injuries. It did, however, cause an evacuation within a half-mile radius as a precaution at two in the morning.

Enough of practically any refrigerant by nature is more or less toxic in certain conditions. Although, since ammonia is rated has a B2L toxic and A3 flammable refrigerant, facilities are experiencing higher liability costs which include the need to comply with strict and costly hazardous materials safety requirements. These safety requirements dictate where some companies choose to locate any new ammonia based refrigeration facilities – in rural areas away from the general public. But many existing facilities located in populated areas are considering alternative refrigerants, such as R744, that offer lower health risks and overall costs.

Ammonia is also one of the most efficient alternative refrigerants in use. That use, however, is almost entirely limited to industrial manufacturing and distribution applications due to ammonia’s single largest drawback; its high toxicity.

Ammonia (R-717) is unique among industrial refrigerants currently in use in that it is not a halocarbon like most other commonly used refrigerants. It is a naturally occurring chemical (NH3) that consists of nitrogen and hydrogen. Almost  all other refrigerants are a combination of carbon and halogens, the group of elements that includes fluorine and chlorine. This factor sets ammonia apart from the vast majority of other refrigerants by limiting its effects on the environment. It has an Ozone Depletion Potential (ODP) rating and a Global Warming Potential (GWP) rating of 0. Only CO2 comes close with a GWP of 1.

all other refrigerants are a combination of carbon and halogens, the group of elements that includes fluorine and chlorine. This factor sets ammonia apart from the vast majority of other refrigerants by limiting its effects on the environment. It has an Ozone Depletion Potential (ODP) rating and a Global Warming Potential (GWP) rating of 0. Only CO2 comes close with a GWP of 1.

Not only is its benign effect on the environment a point in favor of its use, but ammonia has excellent qualities as a refrigerant. It has for instance, the highest refrigerating capacity per pound of any refrigerant and a number of other outstanding thermal properties that make it popular for many industrial refrigeration applications.

With regards to R-404A, the main alternative to ammonia in industrial, processing and manufacturing applications, the two are nearly equal in various factors of their efficiency. R-404A is more commonly used in Europe for these types of applications whereas ammonia predominates domestically. According to one analysis, “in terms of relationship saturation temperature/pressure, volumetric cooling capacity, thermodynamic efficiency of the reference ideal cycle” they are practically equivalent. R-717 however, does have certain comparative advantages.

Ammonia Refrigeration for Cold Storage Applications

One of the most important factors in a refrigerant’s performance is its heat transfer capability. The boiling point of R-410A is -55°F but for ammonia it’s only -28°F, almost half of that of R-410A which indicates that much less energy is required to achieve the same amount of work, or in the case of refrigeration — cooling.

When comparing the efficiency of compression process using reciprocating compressors, ammonia only performs at a modest 10% edge over R-404A. But with screw compressors, ammonia’s advantage increases hand-in-hand with increases in the pressure ratio employed.

A further benefit of R-717 flows directly from its efficiency. An ammonia-based system requires less electricity, resulting in lower operating costs. When used with screw compressors, ammonia requires less energy to achieve the same efficiencies compared to R-404A.

Even compared to other industrial refrigerants, ammonia also performs favorably. In fact, it does so well, a CO2 (R-744) compressor manufacturer recently touted a study that showed that with their compressors (enhanced) R-744 systems have finally reached parity with R-717 systems in warmer climates. The report goes on to say that in cooler climates these systems have even achieved gains over ammonia systems. But CO2 still entails some perceived challenges for some operators. These include higher operating pressures that require the use of specialized piping and the need for CO2-specific control valves and a type of condenser that also works as a gas cooler under certain conditions. Although CO2 is like NH3, a refrigerant that’s been around for a very long time, it is still fairly new to many perspective users.

Another consequence of ammonia’s high volumetric cooling capacity of is the need for less piping than would be required for halogenated refrigerants. Narrower diameter pipe can be used with R-717. This in turn further lowers the cost of using ammonia by making installations less expensive with less piping needed.

On the flip side of ammonia’s consideration, it tends to become corrosive to copper, brass and other non-ferrous materials when it combines with water. Copper is commonly used in refrigeration equipment for halocarbon systems. It’s not an option for systems using R-717. Another concern is its behavior with oil. As with almost any mechanical system, refrigeration systems require lubrication to reduce friction in moving parts extend their durability. Ammonia is non-miscible with oil, so systems in which it’s used must be designed to account for this characteristic and prevent oil from pooling in heat exchangers and thereby reducing efficiency.

Ammonia’s Limitations in Industrial Refrigeration

On the basis of environmental and performance factors, ammonia as an industrial refrigerant would seem to be an excellent choice. But there are other considerations that come into play when assessing its practicality for various applications in industrial and distribution facilities’ use.

In a particularly a bad string of events in 2016 that included an ammonia leak at a Shamrock Farms facility in Phoenix which resulted that April in multiple people complaining of burning eyes. A month earlier, a Boston warehouse worker died from an ammonia leak. And a month before that, nine people were sickened from a leak at a Brazilian fertilizer plant. In December of 2015, two men working in a nitrogen plant in Canada were sent to the hospital after an ammonia leak. One succumbed to his injuries.

A meat processing plant in South Carolina experienced an ammonia leak in 2018 that fortunately did not result in any deaths or injuries. It did, however, cause an evacuation within a half-mile radius as a precaution at two in the morning.

More recently, in 2020, ammonia accidentally released from a meatpacking plant in Texas killed more than 5,000 fish in a nearby creek. While ammonia systems are safe and efficient. provided the ammonia stays contained in the systems, as an article reporting the incident stated: “ammonia is highly corrosive and can injure or kill people who inhale it according to the U.S. Department of Health and Human Services.” It’s news like this that makes prospective users in consumer-facing business weary of its adoption.

Enough of practically any refrigerant by nature is more or less toxic in certain conditions. Although, since ammonia is rated has a B2L toxic and A3 flammable refrigerant, facilities are experiencing higher liability costs which include the need to comply with strict and costly hazardous materials safety requirements. These safety requirements dictate where some companies choose to locate any new ammonia based refrigeration facilities – in rural areas away from the general public. But many existing facilities located in populated areas are considering alternative refrigerants, such as R744, that offer lower health risks and overall costs.