Which Refrigerants Are Typically Used in a Food Process & Production Refrigeration System?

Small Facilities

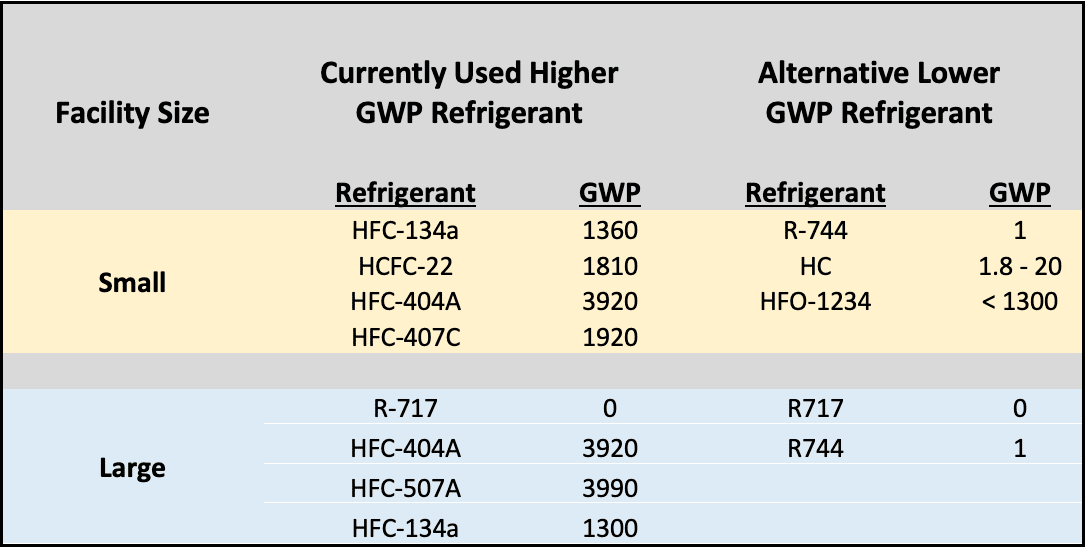

Non-flammable refrigerants with low toxicity are widely used currently, such as those belonging to the family of hydrofluorocarbons (HFCs). However, due to their high Global Warming Potential (GWP), regulatory mandates are requiring countries to progressively reduce or phase out their use.

Alternatives to HFCs would include the use of low-GWP and natural refrigerants:

- Hydrofluoroolefins (HFOs) is a family of refrigerants with a very low GWP, however, their availability, current cost, and mild flammability behavior limit their widespread use. In addition, the long-term accumulation of their decomposition residuals in the environment has not been studied and evaluated.

- Hydrocarbons (e.g. Isobutane, Propane) are used in some applications, but only for very low refrigerant charges due to their high flammability.

- Carbon dioxide (CO2) is rapidly coming on strong. The low environmental impact as well as the progress made in the designing of CO2 loops makes this a realistic and promising sustainable alternative.

Larger Facilities

Ammonia has traditionally been used in large cooling production loops. The downside to using ammonia though has always been its toxicity. When it comes to reducing the hazards and regulatory burdens associated with this refrigerant, some approaches have been used for a long time, while others have been advancing recently:

- For chilling, the use of a cooling distribution loop based on a secondary refrigerant (such as propylene glycol) is a technology that has existed for a long time. It significantly reduces the quantity of ammonia present in the system, and therefore dramatically improves the overall safety of the facility.

- For freezing, the use of two-stage, cascade systems with, for instance, HFC-R134a or ammonia in the high-temperature stage and CO2 in the low-temperature stage, also reduces the ammonia charge and its inherent risk.

- The progress made in designing CO2 loops has increased the use of full CO2 refrigeration systems, especially for freezing and low-temperature warehouses.